2026: The year of the product complexity backlash?

As we move into towards the middle of January 2026, I am noticing a subtle but meaningful shift in how physical products are being discussed, specified and commissioned. It is not loud or headline grabbing. There are no grand declarations or manifesto moments. Instead, its showing up in quieter conversations with clients, colleagues and members of ‘Joe Public’ who are beginning to question whether more complexity genuinely equals progress…

This does not feel like a rejection of innovation. It feels more like a recalibration. A growing willingness to pause, look at what has accumulated over the last decade, and ask whether the added layers are actually serving the people expected to live with these products day-to-day.

Moving away from lock in and over specification

Across a range of projects, there is an increasing appetite to move away from lock in and over specification. Clients are actively asking for products that are simpler, more open, easier to understand and easier to maintain. There is a renewed interest in things that feel timeless and serve longer rather than being optimised for a short upgrade cycle.

In practical terms, this often translates into fewer proprietary components, fewer dependencies and a clearer separation between what is essential and what is optional. The focus shifts back to fundamentals. Does the product do its job reliably? Can it be repaired without specialist intervention? Will it still make sense five or ten years from now? Who supports it if the ‘mothership’ falls into insolvency?

This is particularly noticeable in mobility and transportation, where escalating complexity has been accompanied by escalating cost. Bikes and cars alike have moved towards ever more intricate systems, often justified through finance models that soften the immediate impact but ultimately drive the cost of mobility upwards. As long as the answer to rising prices is simply to offer PCP, the underlying issue remains unresolved.

What feels different now is that this approach is being questioned more openly…

Challenging the Cost of Transportation - Slate Auto’s $25k Pick-Up Truck

Presence over always on

Alongside this is a growing desire to step away from the assumption that products must always be connected, monitored or mediated through software. The appeal of being permanently online is wearing thin. Notifications, dashboards and alerts are no longer universally seen as value adds. For many, they are a source of friction and distraction from the things in real life that are passing you by…

There is a renewed appreciation for products that support being present rather than demanding attention. Objects that work quietly in the background, without hooks for engagement or dependence on an ecosystem. This is not about nostalgia. It is about mental load, trust and freedom of thought.

Even so, the instinct to add features remains strong. Lego’s recent Smart Brick embeds lights, sound and sensing into a system that has historically succeeded by staying deliberately simple. Whether this genuinely expands play or merely introduces a layer of direction is open to interpretation, but it serves as a useful reminder of how easily complexity is introduced under the banner of progress, even in products whose enduring value has come from restraint.

Lego’s ‘Smart Brick’ Ecosystem - Launched at CES 2026

This is about trust, not technology

What sits underneath much of this backlash is not resistance to progress, but a growing reluctance to accept it on trust alone.

Over recent years, people have been asked to absorb higher costs, greater complexity and reduced ownership in the name of progress. Sustainability and net zero remain directionally right, but for many they have become increasingly abstract ideas, delivered through finance models, software layers and distant promises rather than tangible improvements in lived experience.

When progress is felt primarily as added cost, fragility or loss of agency, belief starts to erode. That erosion is not ideological. It is experiential.

The response now emerging feels less like rejection and more like a demand for clarity. A desire for progress that is legible, explainable and felt. Products that are simpler, more repairable and more affordable are not a step backwards. They are a way of rebuilding trust by aligning intention with reality.

This is about trust, not technology.

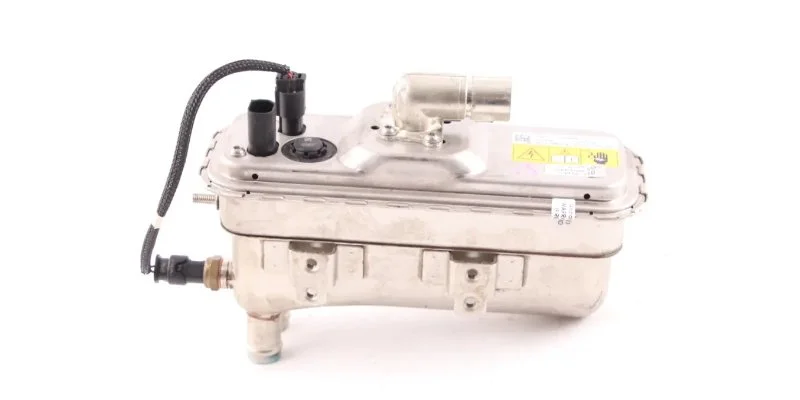

The PTC heater that failed on my BMW i3, 4 years & 25k miles off of the production line. Essentially a kettle that’s irreparable, over £1000+ to replace and also, for some unbeknown reason, linked to the DC fast charging circuit.

Meanwhile, the heater in our 20 year old, 120k mile VW Caddy continues to power on…

Designing for circularity as a commercial imperative

It is encouraging to see this shift reflected in the growing momentum behind initiatives that place circularity, longevity and repair at the centre of design practice. Programmes such as the Design Skills for Circularity pilot, which I will be participating in later this month, signal a more joined up approach between designers, manufacturers and policymakers.

What is notable is not just the intent, but the level of commercial and corporate engagement. Organisations such as the Design Council are helping to frame circularity not as a constraint, but as a route to resilience and long term value. This aligns closely with what I am hearing from clients who are increasingly aware that complexity carries risk, and that simplicity can be a strategic advantage.

A quieter but meaningful shift

None of this suggests a sudden reversal or a single defining moment. The products launching in 2026 will not look radically different overnight. But taken together, these signals point to a backlash against unnecessary complexity and a renewed respect for products that earn their place through reliability, affordability and clarity of purpose.

If there is a revolution underway, it is not driven by new technology alone, but by a reassessment of what progress should actually feel like. And I’m here for it!

Case in Point: Yoto’s ‘Mini Player’

Does this resonate?

If you’re working through similar questions around simplicity, repairability or long term product value, feel free to get in touch. These are the conversations I’m increasingly having with teams across mobility and physical product design.