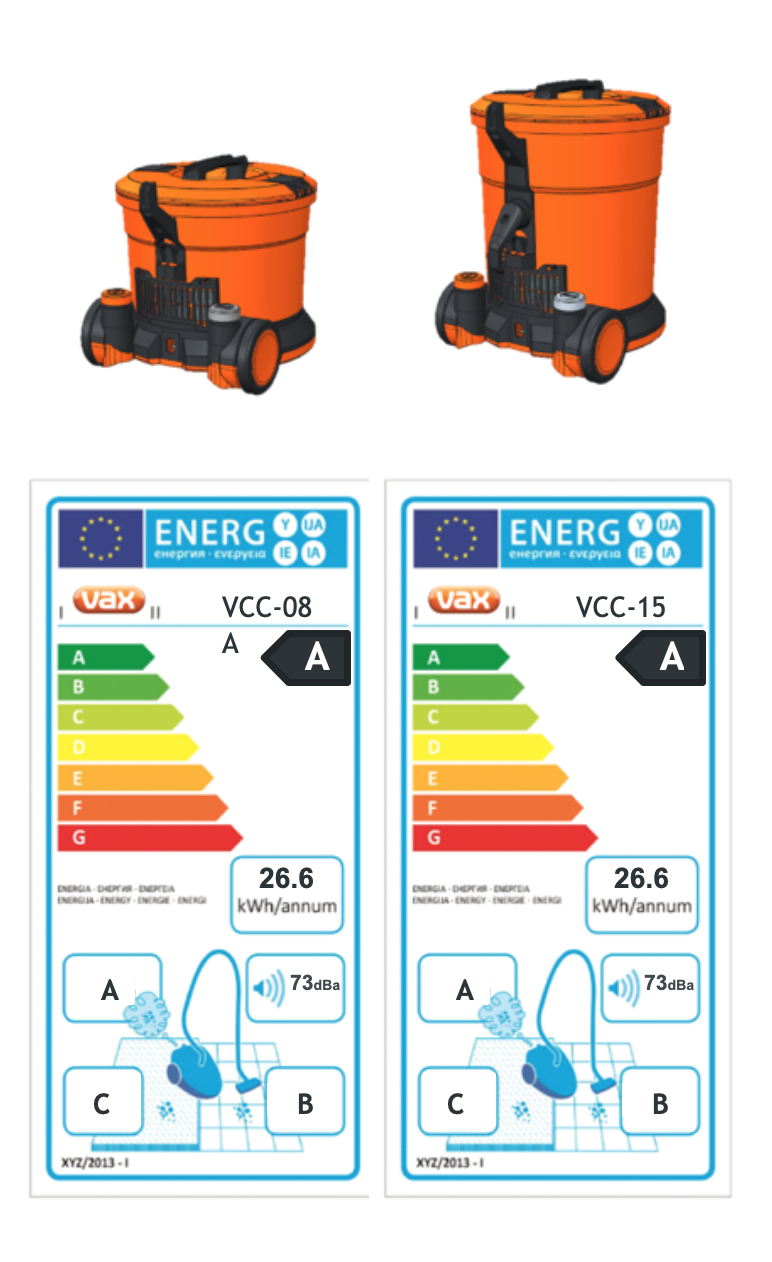

Vax Commercial - Ecodesign Energy Label

Design-for-compliance, manufacturer implementation & range expansion of a category-leading product line in time for the 2013 EU Ecodesign energy label rollout.

Duration: 18 Months

Stages: Concept to Mass Production in South-East Asia

Basis: In-House Design Engineer

-

Vacuum cleaners used to be sold on the premise that the higher the motor wattage, the better the machine.

The reality is that these machines were inefficient and noisy.In 2013, the EU introduced eco-design energy labelling to this product category. This capped motor power at 900W and assessed noise emissions, exhaust particle emissions, dust pick up on hard floors, dust pick up on carpets and kWh/annum power consumption.

This required all vacuum cleaner manufacturers to redesign their products.

The team at Vax Commercial identified this rule change as an opportunity to leverage to gain market share.

-

Matt’s role was to first convert the brand’s VCC-08 model into a category-leading ‘A-rated’ machine.

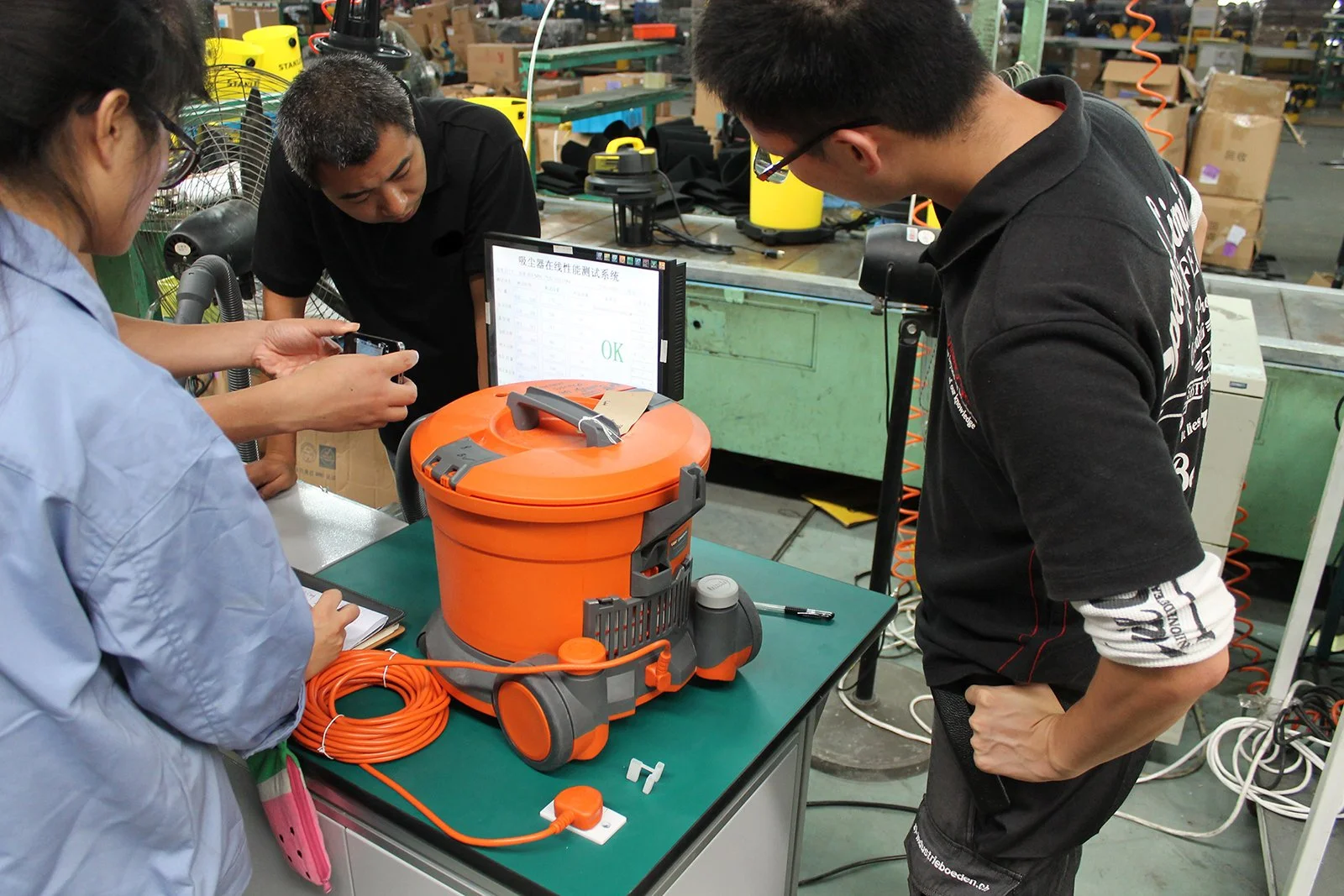

This consisted of maintaining the external A-surfaces but redesigning the internal air paths, identifying a suitable floor tool, benchmarking motor options and integrating an exhaust HEPA filter.Next, he had to assist in the preparation of the Chinese manufacturer’s facility to oversee tooling trials, trial builds, educate on the new regulations and set up the required end-of-line testing facilities & rework procedures.

The tools & learnings from this machine were to then be reconfigured and used to create a family of complementary machines.

-

Matt successfully led the development of the following machines from concept to market-ready::

VCC-08A (An A-rated iteration of the VCC-08)

VCC-09 (Unreleased)

VCC-10C (A slightly tweaked version of the original VCC-08)

VCC-11 (A 110V version of VCC-08)

VCC-15 (A 15L version of the VCC-08A)

At the time of launch, the 08A and 15 both achieved an overall A-rating, a category-leading position.

The 08A outperformed the prior market leader on 3 of the 6 criteria.

The 15 outperformed the prior market leader on 5 of the 6 criteria.

Prototype thermocouple testing

Exhaust HEPA cartridge filter prototype

VCC-08A T0 tooling trial inspections

VCC-08A Engineering build

Setting up end-of-line test equipment in China

VCC-08A Promotional material

VCC-15 Tool storage & cable tidy development

VCC-15 Pilot production builds

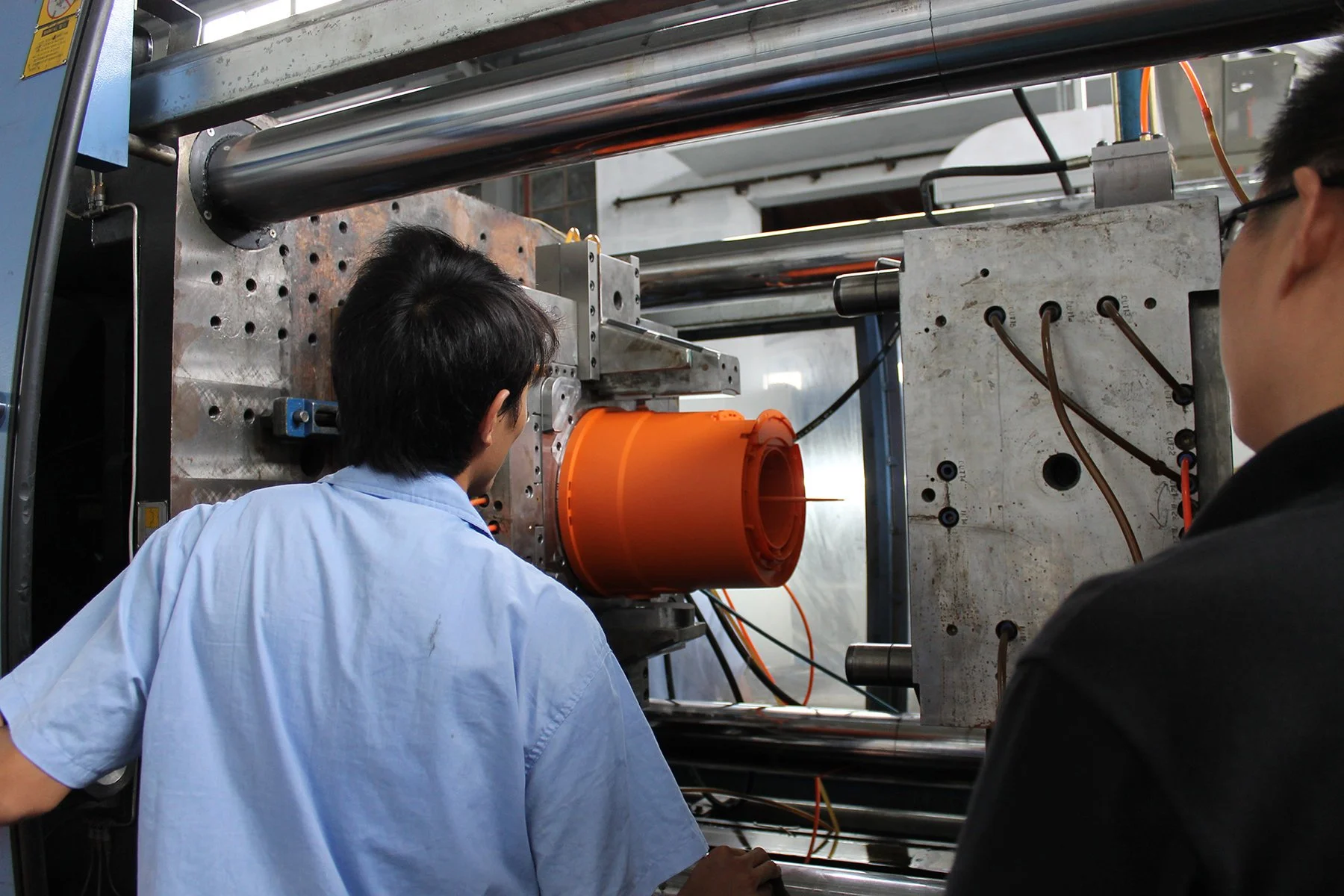

VCC-15 Drum T0 injection tooling trials

ISSA Interclean 2014 Show Prototype