EAV Cargo

Transforming a startup’s MVP into a durable, standards-compliant, positive margin, and production-scalable, commercial electric vehicle. Built in the UK.

Duration: 6 Months

Stages: Concept to Production in the UK

Basis: In-House Lead Engineer

-

EAV was founded during a time of high investor confidence in the micromobility EV sector.

In the wake of the COVID bicycle boom, the landscape had evolved and investors were seeking rapid returns on their initial investment.

Matt joined the second wave of staff tasked with transitioning EAV through this phase.

-

In his role as lead engineer, Matt was responsible for the tactical delivery of four main goals:

Significantly reduce BoM costs

Unblock production capacity bottlenecks through improved DFA (design for assembly)

Improve product durability; reducing customer OpEx

Delivery of additional models

-

During his tenure, Matt was able to deliver the following:

> £500 BoM cost reduction with no impact on perceived quality

Chassis redesigned in compliance with draft DIN79010-4

Harnesses simplified, value engineered & moved to a scalable architecture

Tolerance stacks resolved in the chassis & front axle assemblies

Worked with suppliers to rectify DFM (design for manufacture) challenges in both the UK and USA

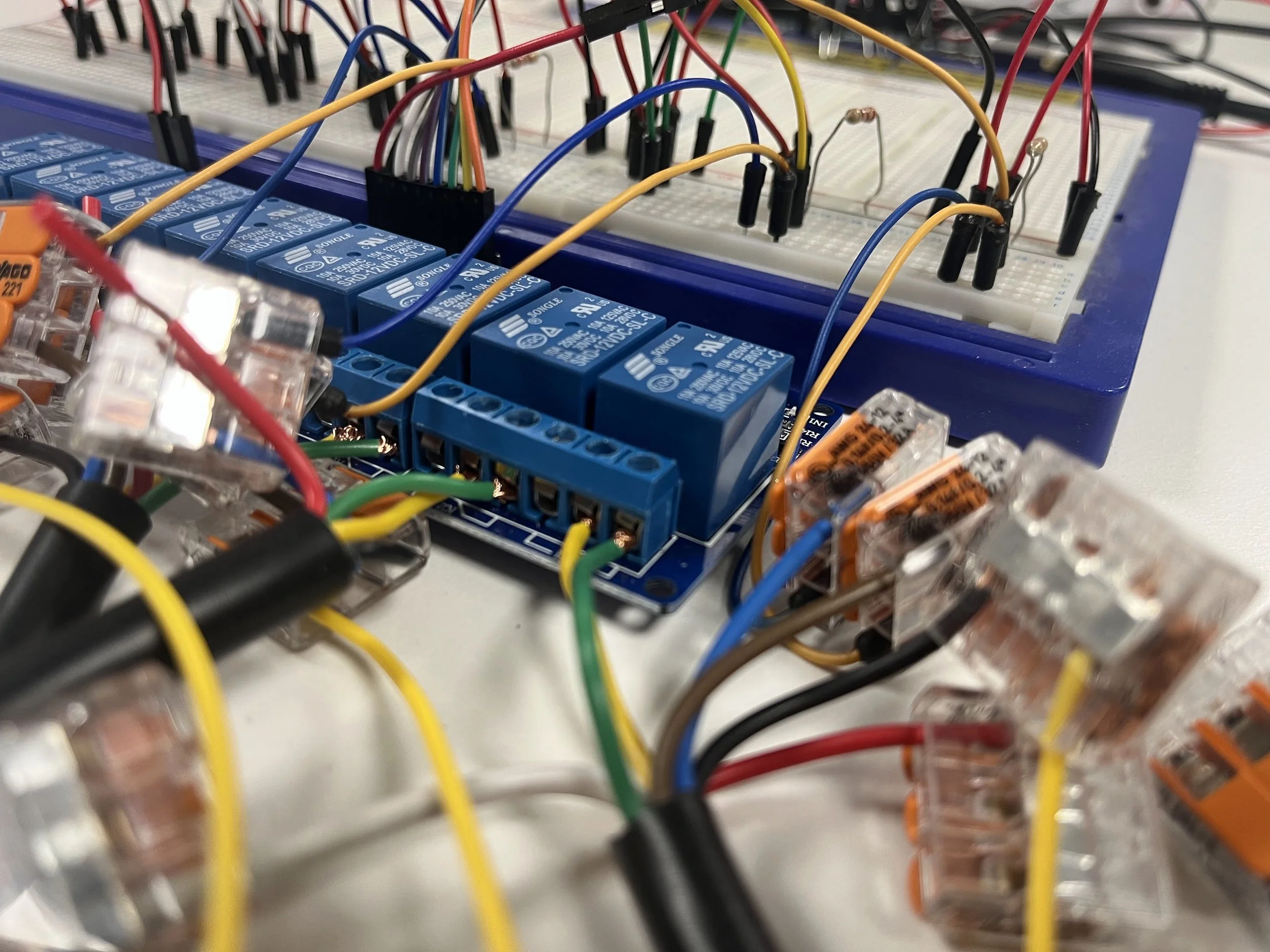

Oversaw delivery of the Cage variant, including developing the entire electrical architecture

Upskilled the in-house engineering team

Collaboratively developed and implemented a business-wide stage-gate/milestone process

Chassis frame components tolerance stack rectification

Hub tolerance stack rectification and redesign to improve ease of servicability

Portion of the chassis FEA development completed in Altair's SimSolid

Ensuring compatibility with alternative braking systems

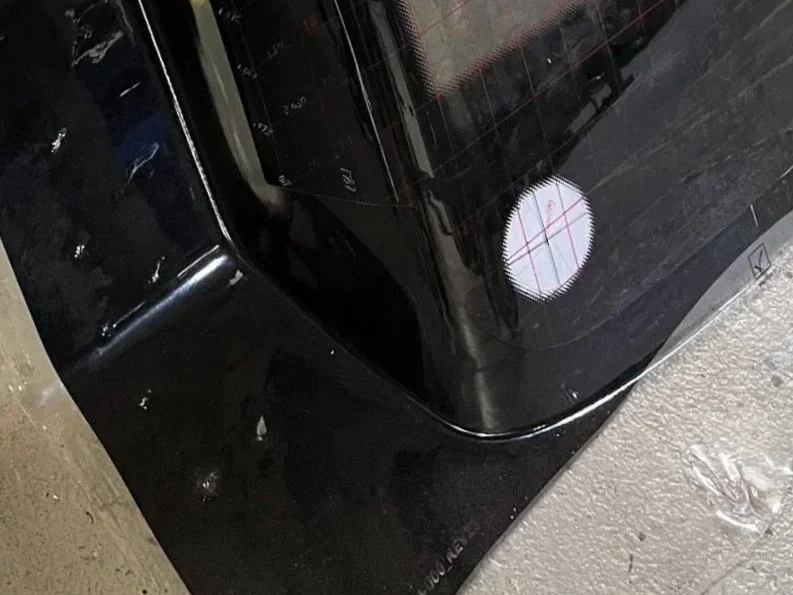

UV Exposure testing on the RIM molded front bumper

New harness optimised for scalable production and cost efficiency

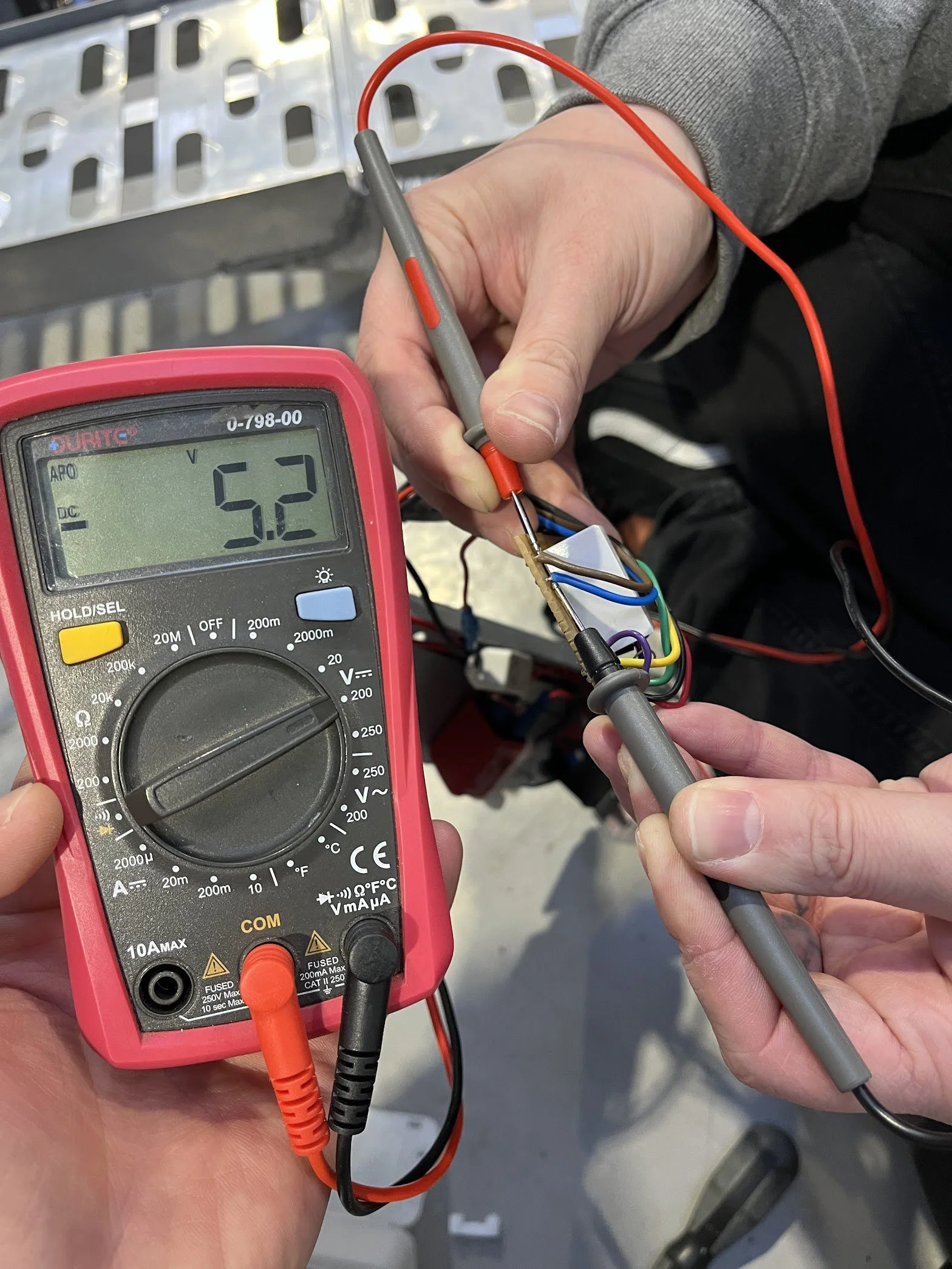

Control board reverse engineering, fault diagnosis & redesign

Arduino-powered PCB fatigue cycle testing rig

On-site DFM review & ideation with a Chicago-based screen manufacturer

Engineering build prototype of the EAV Cage model